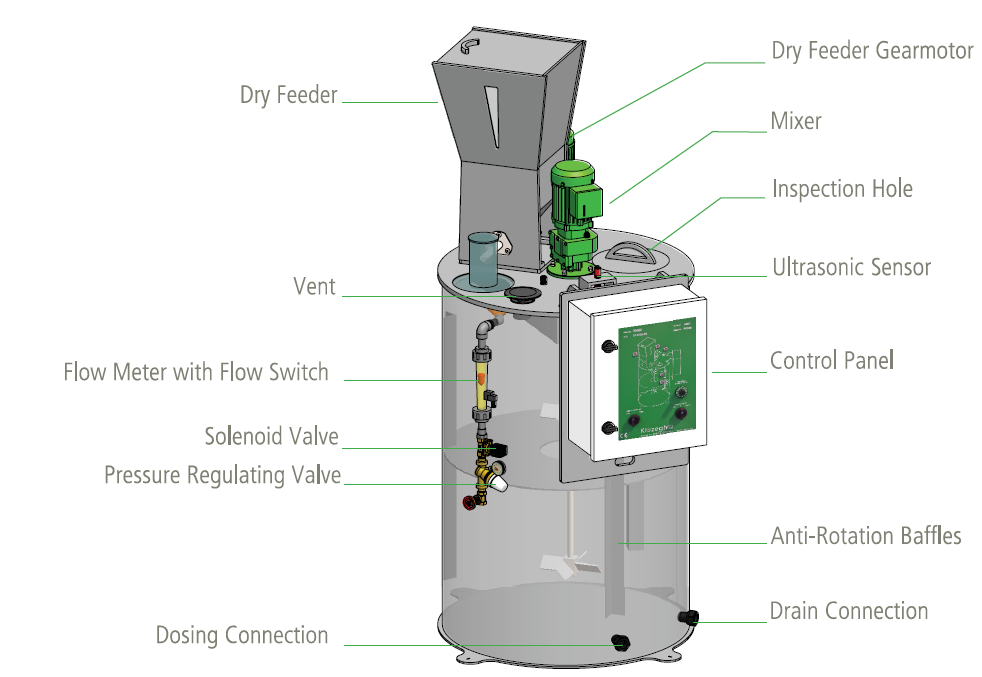

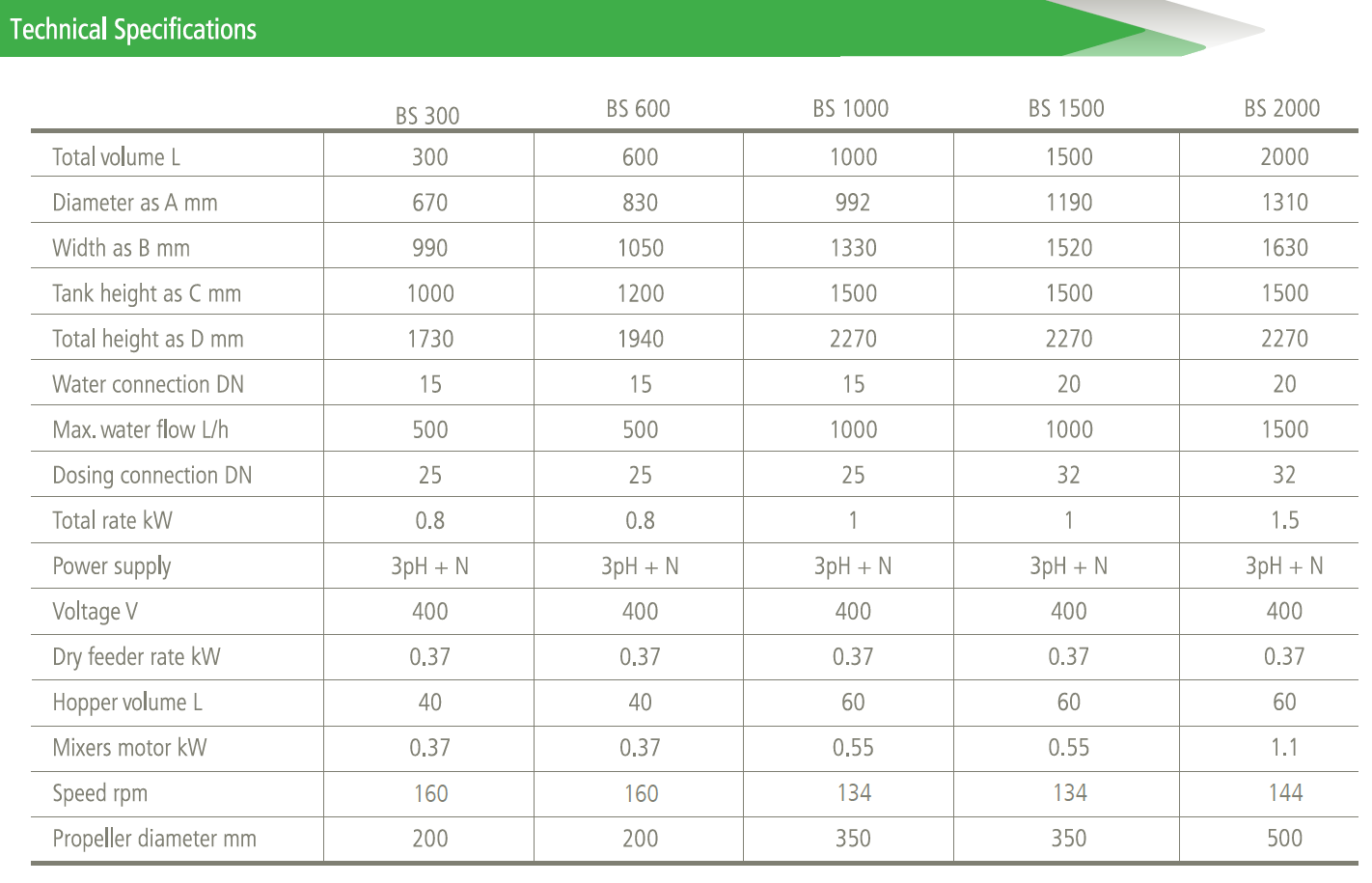

BS models are complete systems to dilute powder chemicals with water in batch mode if dosing with standard dry feeder and compatible with HDPE and stainless steel, in adjustable variable concentrations ratio 1:5. Built as skid principles where all components are connected and tested make it easy electrical and hydraulic installation saving time and money. Easy maintenance and operation procedures make them ideal systems used to prepare carbon and lime suspensions, soda ash or even polyelectrolyte solutions that require batch preparation process.

These systems are constructed of high density polyethylene of cylindrical geometry that can optionally be built in double deck to individualize two volumes, the level of available solution is controlled by an ultrasonic level probe that indicates the level by the measurement of the distance to the liquid, at its low level it initiates the reset process by opening the solenoid valve and at the high level it stops the dilution water entering. The batch preparation volume can thus be controlled by the cycle start height adjustment. Whenever water enters, the powder dispenser will run simultaneously to return the solution to the concentration set by the operator.

Optionally some optional enhancements are available such as a hopper dust detector, heating resistor on the powder dispenser screw that prevents rough cooling, and the formation of lumps immediately before powder product enters the hopper chamber. preparation, another option available is the extension of the standard hopper of 50 liters in 100 liters or even in 200 liters, these last options imply that there is a change in its construction, for capacities of 100 and 200 liters the hopper will have to be built in HDPE but the hopper (which includes the dosing screw) must be 316 stainless steel.

This content is restricted to site members. If you are an existing user, please log in.

New users may register.