Automatic systems “in situ” production from diluted solution with 2% chlorine dioxide concentration by the reaction of 9% hydrochloric acid and 7,5% sodium chlorite concentrations. In the environment the chlorine dioxide is a greenish gas, very instable in high concentration, but solvable in water. Because it don´t hydrolysis, it has a low degradation in ppm´s concentration when it is protected from the light.

The fact that is a good oxidant and a cleaner, the efficiency is not changed by the range between 4 and 10 pH, this not happens with sodium hypochlorite. It is used like an agent against the legionella bacteria, biofilm, algae and smells, reduction of trihalomethanes and chloramines, elimination of iron and manganese and it is made my chemical oxidation and filtration. It is used in water treatment, cooling towers, cleaning systems of fruit and vegetables, because it has a high efficiency in the elimination of bacteria in low concentrations.

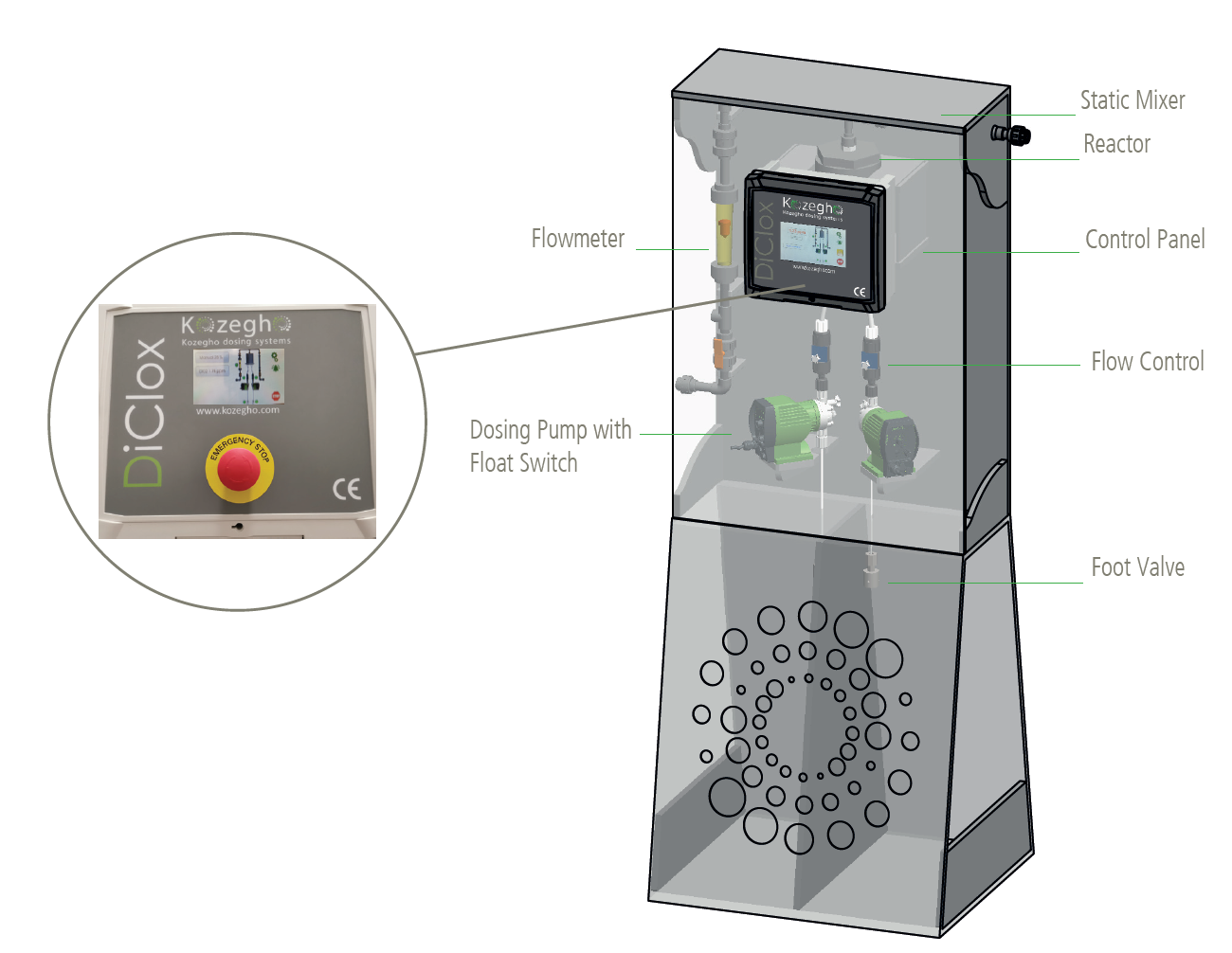

However, the components with high quality and by a principle of plug and play conducted to a simple and fast installation for the users. It has two electromagnetic dosing pumps in PVDF material that is compatible with the chemicals that are used. There are flow detectors in the dosing line and level sensors to confirm the right proportion between the chemicals in the reactor inlet. The water line of the lotion and drag has well as the flowmeter of control and the static mixer ensure the constant dosing of the concentration. All the system is managed by a microprocessor that is used and have incorporated menus with touch screen.

This content is restricted to site members. If you are an existing user, please log in.

New users may register.