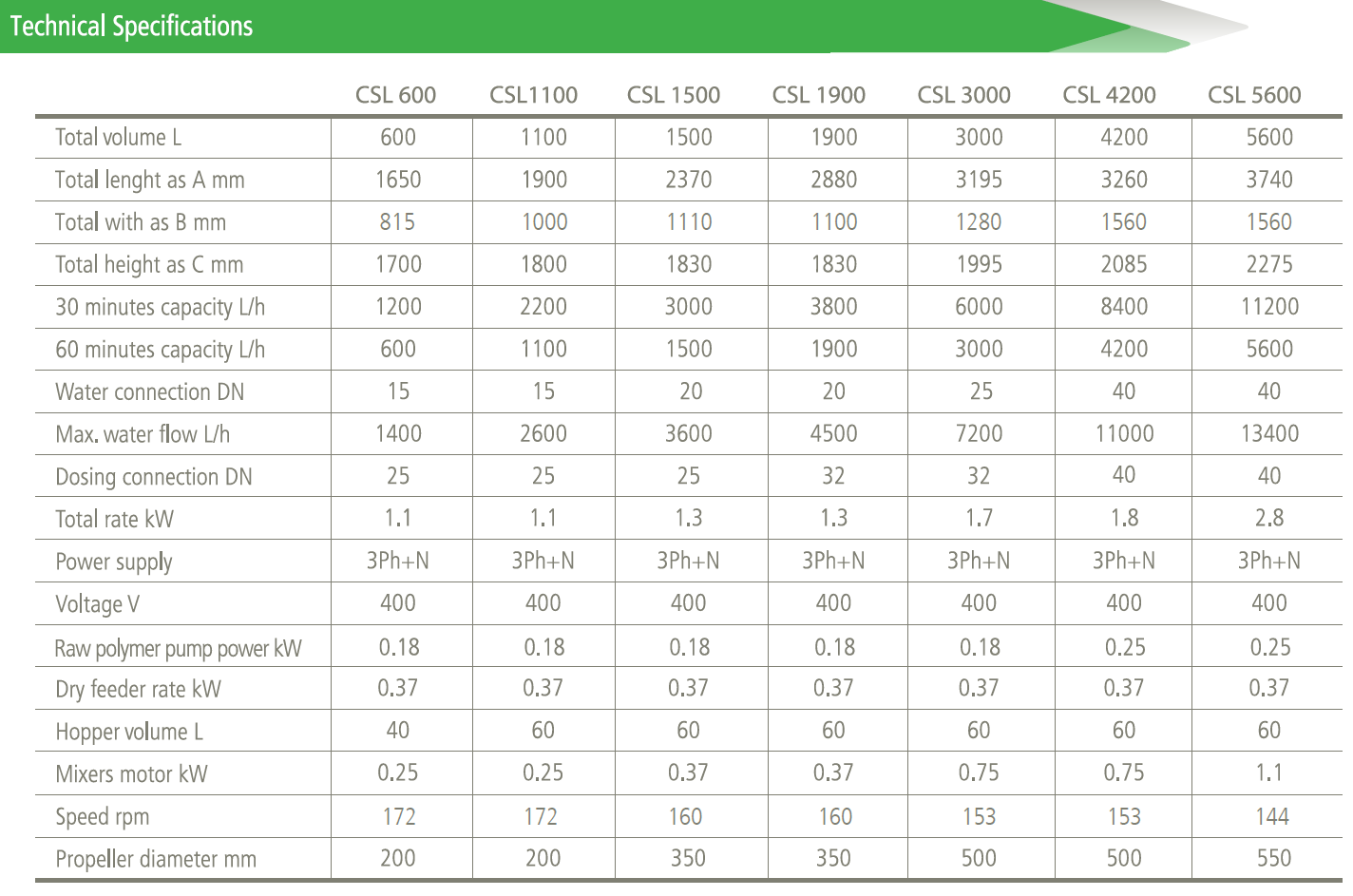

CSL models are complete bivalent systems to dilute powder or emulsion polyelectrolyte’s with water in continues mode to reach concentration solution between 0,05 % and 0,5 %. This high versatility models permit easy switch between powder or emulsion polymer resource that make it management easier with all possible exploration options.

Built as skid principles where all components are connected and tested make it easy electrical and hydraulic installation saving time and money. A friendly configuration, maintenance and operation make them ideal systems used in flocculation process as dewatering, pre-filtration, paper industry…

The extraction capacities for this models just depends the dosing flow rate and for that recommendable understand the indicated volume as a hourly capacity assuming 60 minutes maturation time that is the standard for most polyelectrolyte manufacturers.

Main structure built in HDPE with classic three chambers parallelepiped geometry connected by overflow channels permitting distinct solution volumes for dilution, maturation and dosing.

The duty cycle is controlled by ultrasonic continues level measuring sensor, installed in the dosing chamber, that start the refilling process automatically, opening the solenoid valve and adjusting the dry feeder or dosing pump speed to reach always the selected concentration even with water flow variations.

Configurable process alarms with informative or impeditive action. Mechanical and process fault alarms with independent contact free current signals.

Standard models cover most part of process needs but our engineering department can study with costumers different options to improve present configurations to any situation.

- ELECTRICAL PANEL – “All Siemens inside” with synoptic board and main components signalization by bicolor led, emergency button, PLC S7-1200 for command and control with 4” color display user interface.

- MIXERS – standard in dilution and maturation chambers with 150 rpm motor driver, fast removable coupling system, shaft and 45º plain tetra-blade propellers build in 316 SS.

- DRY FEEDER – With extraction solid center screw and compact Hooper built in HDPE. All systems include heater resistance in extractor tube, intuitive level window and lever sensor in hopper.

- DOSING PUMP – Solenoid and diaphragm controlled by pulses or peristaltic with high head suction capacity suitable for standard or viscous liquids, driven by motor and controlled by speed inverter.

This content is restricted to site members. If you are an existing user, please log in.

New users may register.