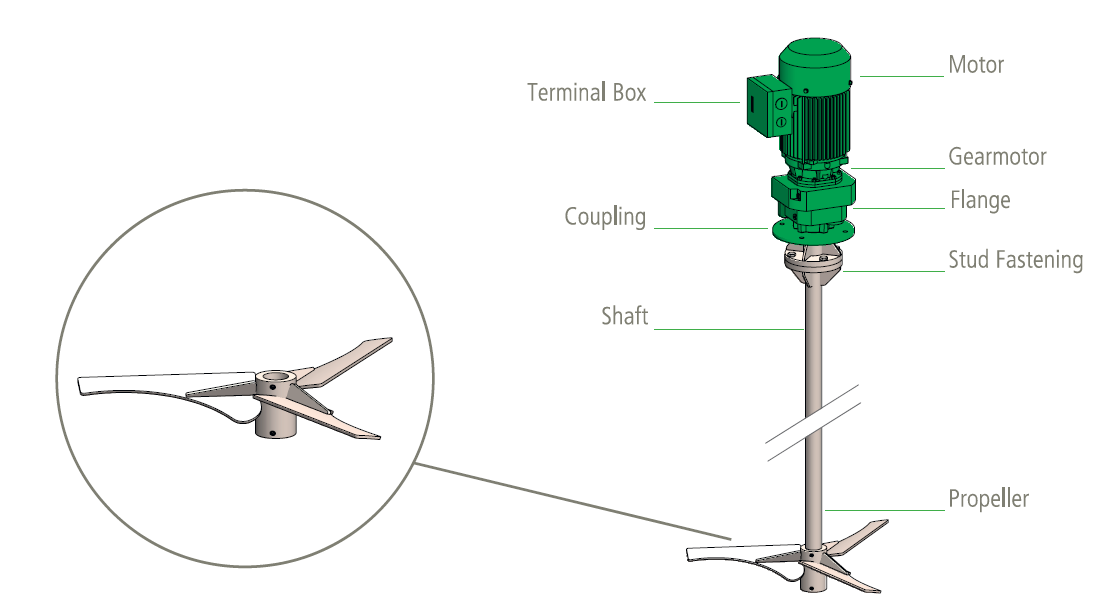

ATL models are low motion mixers with high energy efficiency, triple blade propellers and motor drivers create a vigorous mixing without turbulences and low friction forces. Recommend for large scales systems of liquids moistures, dissolution of solids in water and homogenization applications in water treatment plants and industrial process if compatible with stainless steel.

Variable shaft diameter and length adapted to system dimensions built in stainless steel fixed by removable motor coupling for easy transport and maintenance. Propellers in one peace with three curve blades welded in central block or, in bigger units, three independent parts fixed directly in the shaft. Design for descendent or ascendant liquid flows according to process specifications.

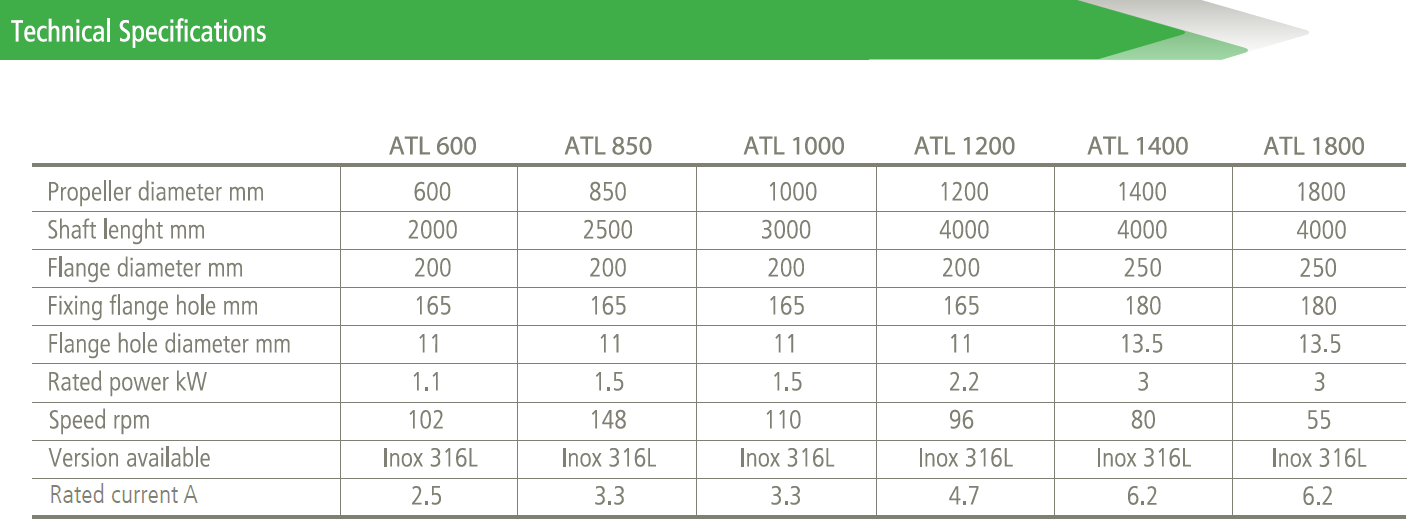

Listed data for standard models in three phase’s version and maximum efficiency but can be configurable with other speed ranges combinations to be adapted at velocity gradients requested in project.

ATL range is a good compromise large chemical dosing and preparation systems, requiring a mixing quality without turbulences and long term energy efficiency in continues mode for complex and sensible products. Should be installed in tanks with Anti vortices baffles and ensure a minimum liquid level for maximum efficiency avoid vibrations in the structure that will create deformations in the tank, possible shaft warping and premature damages in motor drivers.

Designed to working in continues mode and systems with variable liquid level. The moisture viscosity, relative position of mixer in the tank, tank geometry, and height of possible particles in suspension, presence of corrosive vapors and the working liquid level will determine the efficiency of agitation as expected mixer life. In certainly condition can work without liquid.

- High efficiency design models recommendable for large mixing installations with relevant long term energy saving cost.

- All parts in contact with liquid as shaft, propeller and fixing pins built in 316 Stainless steel ensuring long life units.

- Siemens Motor driver system selected with high working factor ratios without any maintenance program during expected life.

This content is restricted to site members. If you are an existing user, please log in.

New users may register.