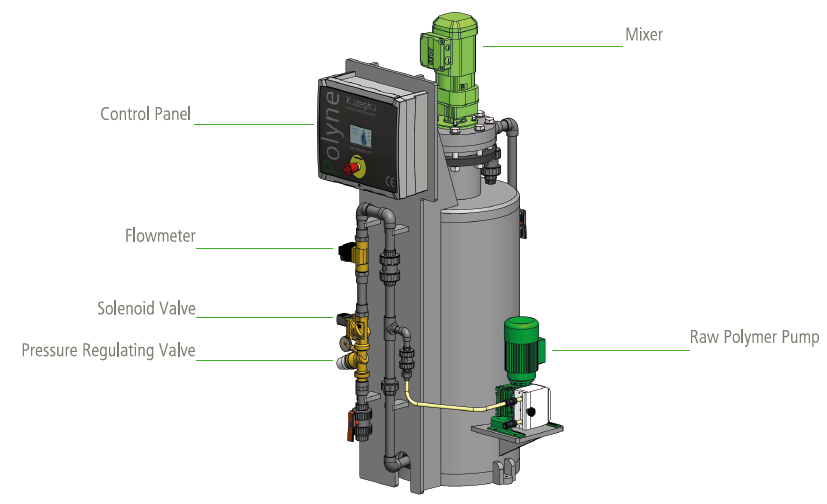

Complete systems built to diluting raw polymer with water in-line mode and adjustable variable concentrations ratio between 40%-100% active polymer and up to 1% of liquid concentration, suitable for dosing with standard peristaltic or diaphragm pump as option. Built as skid principles where all components are connected and tested, make it easy electrical and hydraulic installation saving time and money. Easy maintenance and operation procedures make them ideal systems used in-line dilution polymer. Main structure built in HDPE with cylindrical geometry, mixing chamber pressurized at 1 bar, high in-line preparation/dilution efficiency, reduced dimensional level.

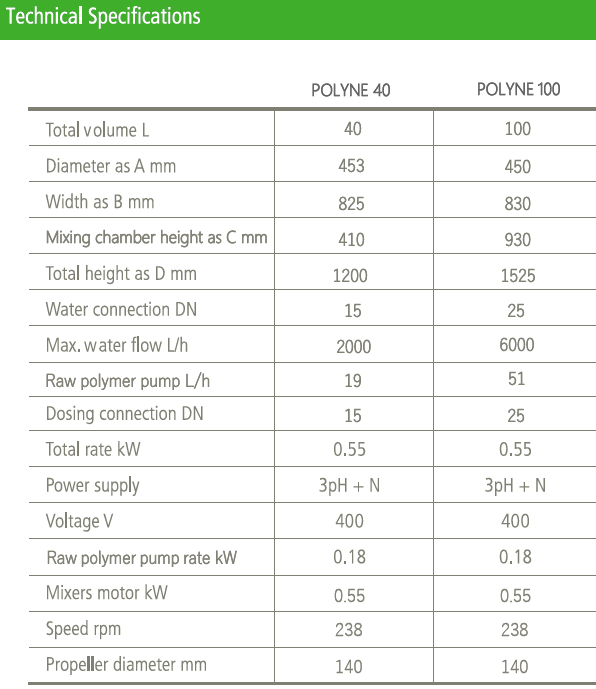

Polyne models have chambers with different volumes to ensure the same maturation time for different raw polymer feeds.

•Reduced maturation and dilution time factors without affecting theefficiency of the polymer preparation process;

•Reduce residential time by 20% using a pressurized tank at 1 bar;

•Significant improvement in the liquid dosing system, guaranteeing yields identical to the non-pressurized tank systems in batch or continuous preparation;

Configurable process alarms with informative or impeditive action. Mechanical and process fault alarms with independent contact free current signals.

Optionally is possible to include a low level sensor contact for raw chemical. A second ultrasonic sensor for the prepared solution storage tank.

Second dilution line, with regulation pressure valve, solenoid valve and water flowmeter.

This content is restricted to site members. If you are an existing user, please log in.

New users may register.